Production display

Four Reasons to Choose Us

1. High cutting precision: complete equipment manufacturing and production, dedicated equipment cutting, neat cuts, smooth surface treatment

2. Aluminum alloy material: stable raw material suppliers, careful workmanship, quality assurance

3. Large amount of spot inventory: various aluminum material warehouses are in stock, so customers do not need to worry about shortage issues

4. Demand cutting: Cut randomly according to your needs to manufacture suitable aluminum products

Packaging and transportation

Packaging details: wooden box packaging

Delivery period: 1 month

1. There is blue PE film or partition paper on the surface.

2. Packaging: export wooden pallet packaging, suitable for moisture-proof and safe for shipping.

3. The maximum package shall not exceed 4500LBS, or as required by the customer.

4. For 1 x 20GP, 25MT can be loaded.

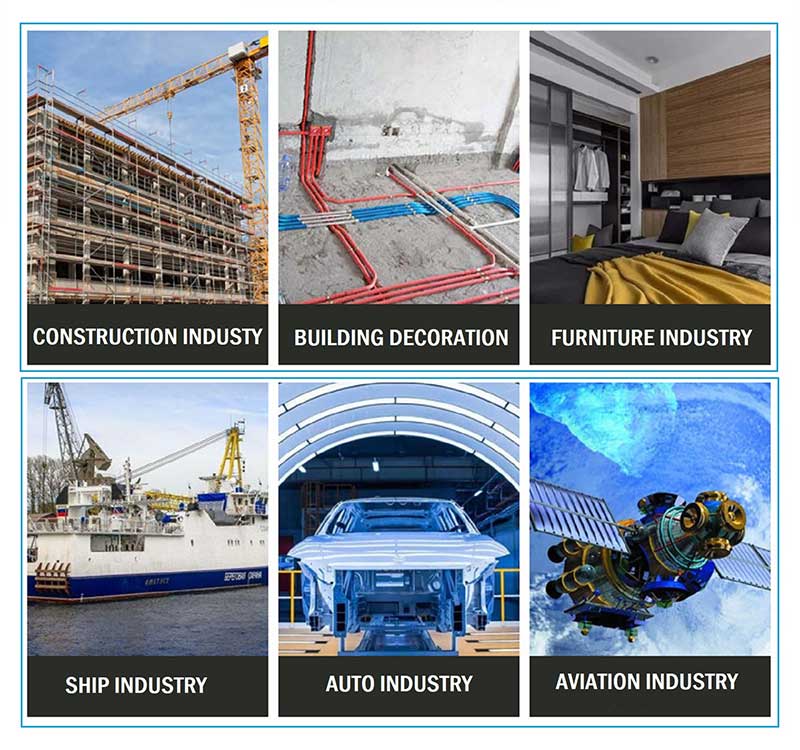

Application scenario

Our advantages

10 years of aluminum processing experience

We focus on: 1 Chemical composition 2 Mechanical properties 3 Surface quality 4 Dimensional tolerance

100% quality assurance policy

Your money is safe here: if our aluminum products do not meet the standards of GB/T3880-2012 or ASTM B209 or EN485, we will refund your money and compensate you for all losses.

ISO 1401 and ISO 9000

The company has passed ISO14001 and ISO9000 certification and is fully capable of providing customers with high-quality products.

Free samples and more than 5000 tons in stock

Equipment display

FAQ

Are you a manufacturer or a trading company?

-------We are an aluminum manufacturer based in Shandong, with more than 20 years of experience since 1999. We warmly welcome you to visit us.

What kind of surface treatment can your company do?

------Our main surface treatments include anodizing, powder coating, wood grain, polishing, wire drawing, electrophoresis, polishing, sandblasting, etc.

What kind of deep processing can you do?

------CNC, drilling, milling, cutting, welding, bending, assembly.

What is the delivery time for samples and batch production?

--------Mold development usually takes 15 days, and mass production takes 25-30 days.